Continuous Duty

During the hunt for an electric motor for a particular application, duty cycle is routinely brought up as an important factor in determining your final motor selection. Often asked is the question of, “Will this application require a continuous duty cycle or an intermittent one?” In other words, will the application be a marathon-type that must endure prolonged, continuous usage or will it be more of a sprinter variety where only short intervals of work will be required?

As a rule of thumb, an application is placed in the continuous duty category when 20 or 30 minutes of uninhibited operation is required. This timespan varies with application and can be determined according to its duty rating—a standard your motor manufacturer can help with once the load, torque, speed, and other variables are made known.

To further expand, it is good to note that this continuous duty classification is temperature driven—if the continuous duty cycle is 20 minutes, that means that it takes 20 minutes for your application, under the rated load, to reach maximum functioning temperature. In essence, it’s the time it takes for motor to reach their hottest possible temperature and still perform normally. Excessive heat can cause deterioration of various motor components as well as inhibit performance factors such as torque.

If an application requires non-stop operation at a set load point, the motor will need to be able to stabilize at a temperature within its temperature rating while running continuously. Generally speaking, the volume of a motor is proportional to the amount of heat that can be dissipated (fan design is also critical for vented motors).

“Generally speaking, the volume of a motor is proportional to the amount of heat that can be dissipated (fan design is also critical for vented motors).”

Intermittent Duty

As you can probably guess, intermittent duty cycles, are when operation occurs on an interval basis. The motors don’t reach their top temperature points, because they don’t run long enough to create and build adequate heat required to significantly raise temperatures.

So basically, intermittent duty applications have less heat to dissipate, which generates space, weight, and cost savings because a smaller sized motor can typically be used. For example, in an application where a specific speed-torque point is required but the duty cycle is for 6 seconds every minute, a smaller motor may work for the application in comparison to the motor required for continuous operation.

As a result, the duty cycle frequently determines the required motor size for a given application.

Click here to read our blog post on Finding the Best Motor for Intermittent Duty Applications.

Groschopp Duty

When choosing a fractional horsepower motor, customers typically have a speed, torque, and power load point they need the motor to deliver. This is a good starting point and a critical step in the process of choosing the correct motor for an application. However, duty cycle can often be overlooked, and this is where your manufacturers can help.

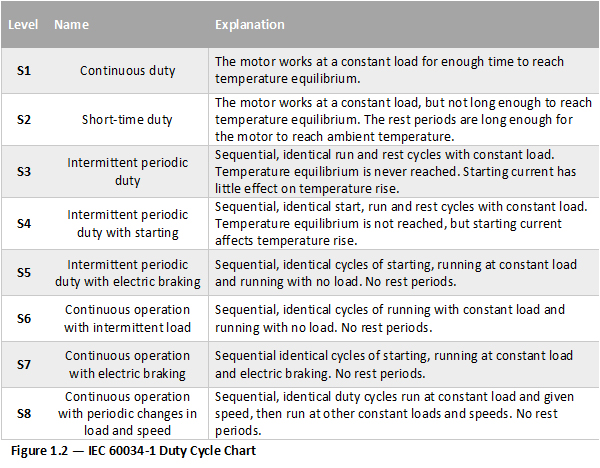

According to the International Electrotechnical Commission (IEC), duty cycle can be broken down into eight categories, which the IEC outlined in the following chart.

Manufacturers need to know what your duty cycle is in addition to your power requirements. However, you don’t have to know which of IEC’s 8 categories it falls into; our trained Groschopp team will help you decide on the correct motor for you and ensure that you are getting the most affordable motor for your application based on the information you provide.

Groschopp has a propriety software program that allows us to quickly search specific duty cycles. We don’t need to use levels, because we use exact numbers to make sure to give customers the best fit.