Back-drive-ability is defined as the degree of ease of which a motor or gear motor can be driven by its attached load when power is removed from the motor.

Typically, a motor is fairly easy to back-drive by turning the output shaft by hand. A gear motor (motor attached to a gear reducer) is more difficult to back-drive depending upon the gear reduction ratio and the efficiency of the reducer. When being back-driven, a gear reducer also becomes a shaft speed multiplier, so the higher the gear reduction ratio, the more torque it takes to back-drive the gear motor.

Typically, a motor is fairly easy to back-drive by turning the output shaft by hand. A gear motor (motor attached to a gear reducer) is more difficult to back-drive depending upon the gear reduction ratio and the efficiency of the reducer. When being back-driven, a gear reducer also becomes a shaft speed multiplier, so the higher the gear reduction ratio, the more torque it takes to back-drive the gear motor.

Advantages & Disadvantages of Back-Drive-Ability

Easy back-drive-ability can be especially useful when moving high-mass loads, where the motor “coasts” as the heavy load comes to a rest. Easy back-drive-ability can also prevent the load from causing damage to the gear motor in some applications. On the other hand, if a gear motor can be back-driven by its application, it could be a safety hazard.

“Power Off” Electro-Magnetic Brakes

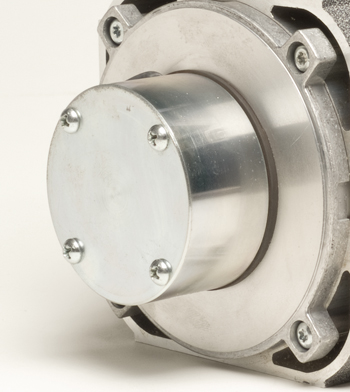

A brake can be mounted to the end of the motor opposite the drive end to minimize or eliminate the back-drive-ability of the motor in an application and hold a load at the last intended position. One type of brake is the Electro-Magnetic brake, which consists of an electro-magnet, a spring, a friction disc coupled to the motor shaft, and two clutch plates, all in a small housing. When no power is applied to the brake and the motor, a friction disc in the brake is clamped between the two clutch plates forced together by a spring, make it a “power-off” brake. When power is applied to the motor and simultaneously to the brake, the electro-magnet in the brake is energized pulling one of the clutch plates away from the friction disc, releasing the brake and allowing the motor shaft to turn. This system can still be back-driven above a certain amount of torque, depending upon the torque rating of the brake. Brakes typically have a holding torque starting at 3 in-lbs. If a 3 in-lb brake is attached to a motor, you would require over 3 in-lbs of back-drive torque to turn the motor shaft by hand. If the same brake was attached to a gear-motor with a 10:1 reduction ratio, you would require over 30 in-lbs of torque (disregarding gearbox efficiency) to turn the output shaft by hand.

An example of an application that can utilize an electro-magnetic brake would be a lift or hoist. In these types of applications a gear motor is used to lift a heavy object. When power is removed from the gear motor, the brake engages and locks the output shaft, keeping the heavy object from back-driving the gear motor and falling.

“Power On” Electro-Magnetic Brakes

Some applications, such as a railroad-crossing arms, may require the system to back-drive. In this application, a “power-on” style of brake is used. This style of brake works opposite of the brake in the first example, as it requires power to engage the brake. Picture a railroad-crossing arm in the vertical position. The brake on the gear motor operating the arm is energized; locking the gear motor and holding the crossing arm up even though power is removed from the motor. In the event of a power failure, the brake would disengage, and the weight of the crossing arm would back-drive the gear motor to the horizontal position: a matter of safety.

>>Looking for information on back-drive and braking. Check out our Tech Tips video on this topic.